Is Industry 4.0 one more buzzword that promises more than it delivers or is there significant value that can be appropriated and replicated to improve your bottom line in a significant and sustainable way?

Understanding Industry 4.0 and using it’s underlying advanced technologies as mobile computing, advanced sensing and IoT creates an enormous value potential for organizations. These technologies generate information and events that create a reliable picture of the real world, besides allowing information to become available in useful time to make a difference. This dual ability to collect and deliver information anywhere, anytime is a tremendous opportunity to simplify the way organizations behave, while reducing the effort and problems that arise from taking educated guesses where decisions are required.

The biggest issue however is not if you should use these technologies but how you should use them to generate the biggest positive impact possible in your bottom line. That’s why you need to consider that just removing paper from the shop floor, although a nice step forward, is not more than coming up very short on a significant investment.

The opportunity is not to eliminate paper, is to have reliable information in real time to anticipate failure and improve both efficiency and effectiveness. You need to move beyond the immediate appeal of the mainstream message (like let’s go paperless) and grab the huge potential lying beneath.

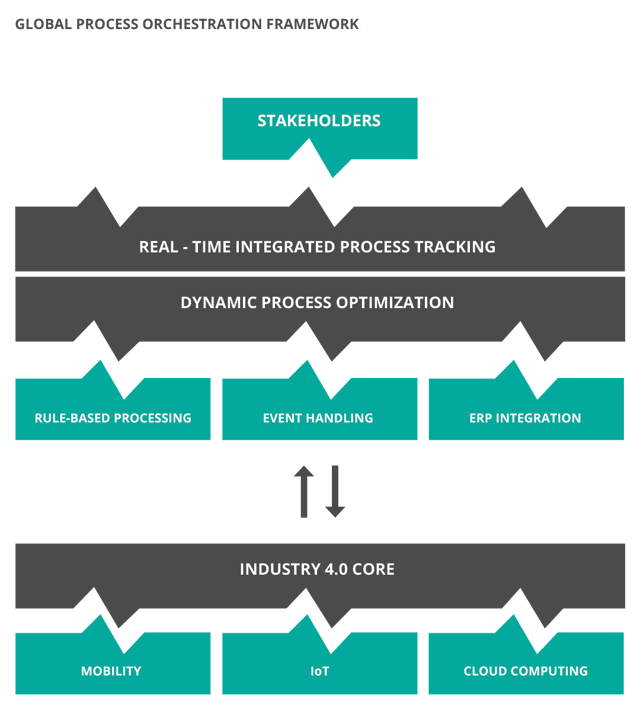

That potential is based on the ability to connect intelligently different events and information to dynamically generate more information that, properly distributed, allows the entire organization to adapt in real time to the changes that happen. This is where you need to focus: how to map an operational landscape that dynamically orchestrates the real-time responses to achieve better efficiency and effectiveness.

The key issues that you need to consider to grab this huge opportunity are far wider than the technologies you need to use and are truly disruptive to your organization. You need to focus on the process and each of its activities, how each process interacts with all relevant internal and external stakeholders and make that interaction reliable, automated and safe. You must assure that your landscape is mapped in such a way that you can easily change the way it behaves, so you can adapt to different business or operational requirements in a very short time span. You need to assure the proper and reliable integration of all components and processes with your business management platforms, making them as stable and as standard as possible to reduce your ownership costs. By addressing these issues and by using these technologies consistently, under a common, process-oriented framework, you’ll be effectively moving beyond the surface and reaching true value: an adaptable and intelligent manufacturing landscape that delivers sustainable return and efficient operations.

Using a common, process-oriented, rule-based framework to map your operational landscape and its underlying real-time events is the cornerstone to leverage IoT technologies and Industry 4.0 concepts, taking them a step further into a stage where all possible value is extracted from the investment made, while assuring operational sustainability and true integration. By mapping a process and its activities under an event driven processing engine, you are able to tap in real-time to all the information made available by IoT and mobile technologies. Processing that event-based information using rule sets to dynamically determine the best possible outcome and using the same technologies to deliver information to the appropriate stake holders (physical, electronic or human), makes your landscape smart, intelligent and adaptable. This allows you to change continuously, without a predefined or static operational schema, adjusting dynamically to demand and events in real-time and understanding, in any given instant, the actual status of each of your processes.

This intelligent and smart landscape delivers critical advantages to your operations. It allows you to anticipate failure, to trigger responses to exceptions automatically, to process automatically thousands of different pieces of information to assess the best possible result and to automate all integration and manual activities that are error prone and time consuming. It effectively means that you’ll be able to own, monitor, control and adjust your operation to changing demand using less resources and with shorter lead times. And this is possible because we can converge a critical set of factors onto a common platform that is aware of the integration requirements, it possesses the required scalability to handle massive amounts of information in real time and is driven by adaptability concepts that allow it to behave dynamically in your terms.

Industry 4.0 is a sound, breakthrough concept that contains the fundamentals to allow you to bridge the gap between the real world and the information systems that map it. But you need to push this concept forward, under a common dynamic process optimization framework to truly make it sustainable and valuable.